Telescopic Cylinders

Single-acting

Melin & Carlsson’s single-acting telescopic cylinders feature a compact design to optimize a high stroke length with small dimensions. The telescopic stages run inside each other with small clearances to maximize the pressure areas on each stage. The cylinders are primarily available with chrome-plated telescopic stages. You can learn more about the various surface coatings we offer here.

There is also a simpler range for lower load pressures where the telescopic stages are roller-burnished without chrome plating. A single-acting telescopic cylinder requires that there is a load to push the cylinder back to the retracted position. Common applications include tipping beds and lift systems.

Telescopic cylinders are typically mounted using a combination of the optional standard mountings: clevis, ball joint, and cylinder tube with eye mount. Eye mounts can also be combined with a cradle, which is appreciated, among other things, for multi-way tipping. The cylinders can be supplied with working pressures of 175 or 210 bars, depending on the configuration.

Double-acting telescopic cylinder

Melin & Carlsson can offer a limited range of double-acting telescopic cylinders. This is not a standard range but an option for larger recurring needs. The pulling function has a relatively low force in the negative movement. We can also provide telescopic cylinders where only one stage is double-acting. This solution combines the compact design of a single-acting cylinder with limited double-acting functionality, for example, to pull the load back over its center of gravity.

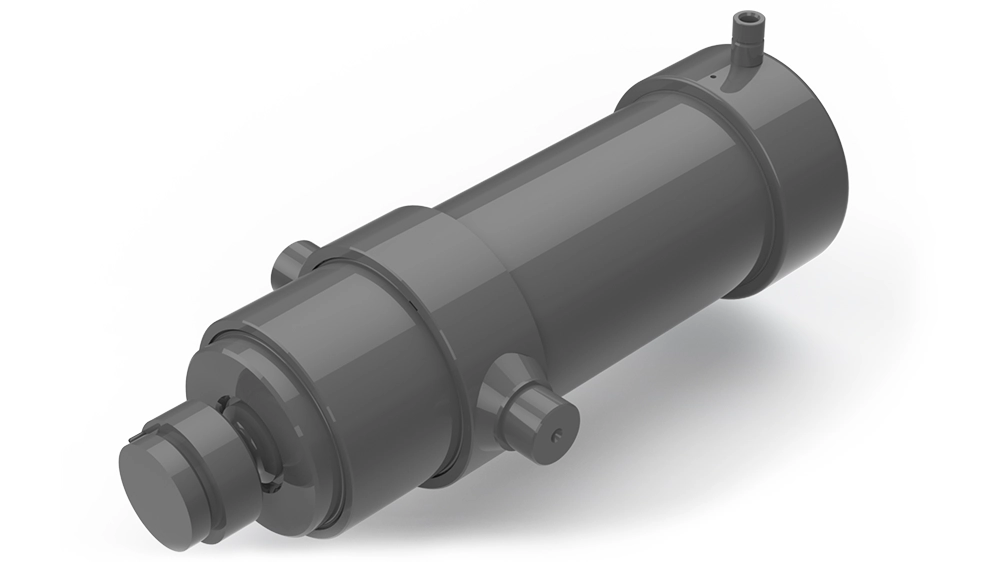

Serie KK: Telescopic Cylinder 210 bar

Single-Acting Telescopic Cylinder where the cylinder is supplied with a complete ball joint at each end, including a weldable ball socket for integration.

Serie KO: Telescopic Cylinder 210 bar

Single-Acting Telescopic Cylinder where the telescopic stages are supplied with a complete ball joint, and the cylinder tube has an eye mount.

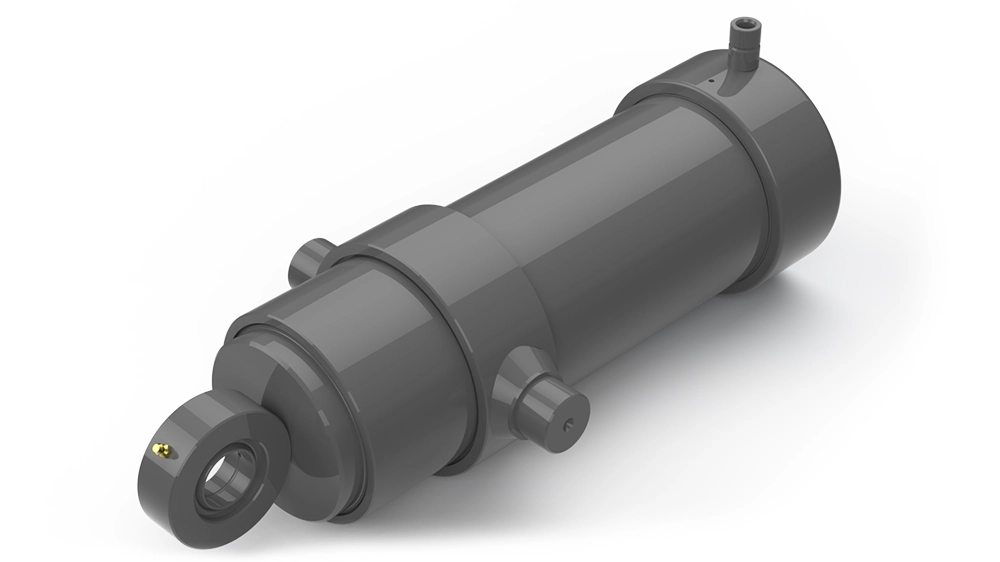

Serie KV: Telescopic Cylinder 210 bar

Single-Acting Telescopic Cylinder cylinder where the telescopic stages are supplied with a complete ball joint, and the cylinder tube has an eye mount, additionally complemented with a cradle for compliance in all axes.

Serie LL: Telescopic Cylinder 210 bar

Single-Acting Telescopic Cylinder with a ball joint mounting at each end.

Serie LO: Telescopic Cylinder 210 bar

Single-Acting Telescopic with a ball joint mounting in the telescopic stages and an eye mount on the cylinder tube.